- Article

Powder Manufacturing-Driven Variations in Flowability and Deformation Behavior of Pure Copper Powders for Cold Spray Additive Manufacturing

- Niloofar Eftekhari and

- Hamid Jahed

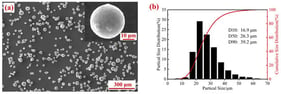

The quality of the feedstock powder plays a key role in determining the properties of coatings produced by cold spray (CS). However, most commercially available powders are not specifically designed for CS, which makes it difficult to tailor powder characteristics for optimal performance. In this study, we examined the cold sprayability of five copper (Cu) powders manufactured using electrolysis, gas atomization, and mechanical grinding. The powders were characterized in terms of their microstructure, particle shape, and size distribution to evaluate how the production method influences powder properties. Powder flowability was measured using a shear cell test, while mechanical properties and deformability relevant to CS were assessed through nano-indentation. The results showed that gas-atomized powders with equiaxed grain structures offered the best combination of flowability and deformability, making them the most suitable for CS. Their spherical particle shape resulted in a lower surface area compared to the irregular electrolytic powder, which reduced inter-particle surface forces and allowed for smoother powder flow. Nano-indentation measurements indicated that the mechanically ground powder with ultra-fine grains and the gas-atomized powder containing fine dendrites had the highest nano-hardness values (HIT = 2.1 ± 0.15 GPa and 1.6 ± 0.1 GPa, respectively). In contrast, the porous electrolytic Cu powder showed the lowest hardness (HIT = 0.7 ± 0.2 GPa). These trends were confirmed by microstructural analysis of the deposited coatings. Coatings produced from the irregular electrolytic powder exhibited limited particle deformation, weak inter-particle bonding, and the highest porosity. Conversely, spherical gas-atomized powders produced much denser coatings. In particular, the powder with the most uniform spherical shape and no microsatellite particles resulted in the lowest coating porosity due to its superior deformation behavior upon impact.

7 February 2026

![Example of deformation temperature stress dependencies in interface of control program obtained for the sample of Ni-Ti alloy after equal angular pressing, hot forging, and annealing reprinting from [20]—raw data.](https://mdpi-res.com/cdn-cgi/image/w=281,h=192/https://mdpi-res.com/metals/metals-16-00194/article_deploy/html/images/metals-16-00194-g001-550.jpg)

![(a) Assembly of the blades on the hub and installation of the propeller on the Andromède [5]. Reprinted with permission from [5], 2023, Springer Nature. (b) Wire arc additive manufactured (WAAM) propeller bracket [7]. Reprinted with permission from [7], 2020, Elsevier.](https://mdpi-res.com/cdn-cgi/image/w=281,h=192/https://mdpi-res.com/metals/metals-16-00192/article_deploy/html/images/metals-16-00192-ag-550.jpg)